Focusing on Customized Intelligent Spraying Machinery and Coating Solutions info@szqihang.com+86-15999524708

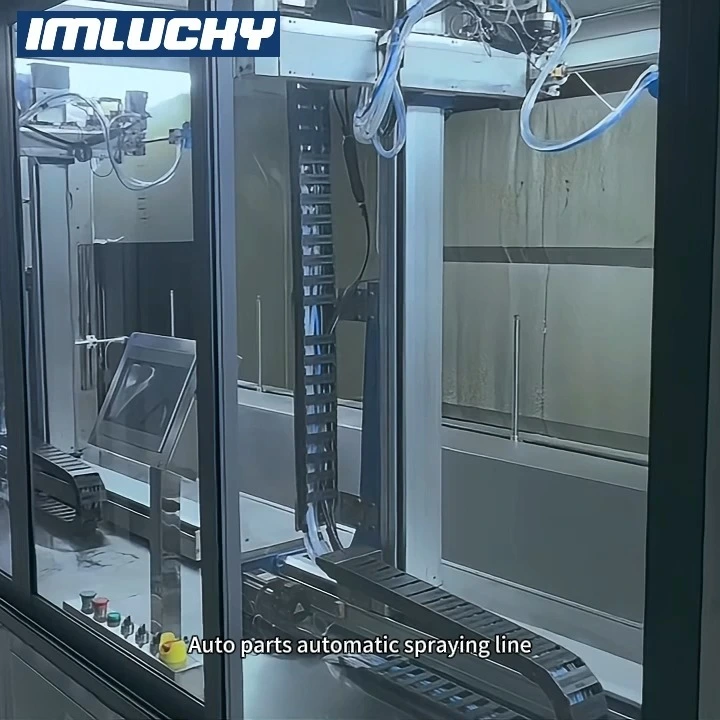

Professional Automatic Painting Line for Automotive Plastic Parts

Are you struggling with low adhesion, dust contamination, or uneven coating thickness on your automotive plastic components?

As a leading manufacturer of automatic painting systems, we provide turnkey solutions specifically designed for high-end plastic surface treatments (ABS, PP, PC, PE). We help Tier 1 & Tier 2 automotive suppliers transition from manual uncertainty to robotic precision.

Automatic Plastic Painting Line Manufacturer /Auto Parts Coating Solution

Still struggling with paint peeling issues on PP/ABS materials?

- We are a leading manufacturer of automated spray painting production lines for plastic automotive parts. We utilize electrostatic dust removal and a dust-free workshop environment to solve poor adhesion and dust contamination problems, helping you increase your yield rate to 98%!

- Upgrade your factory with our automated plastic spray painting system. Reduce paint waste by 30% and lower labor costs by 60%.

- Contact us for a free factory layout design and return on investment analysis!

Applicable scenarios

From pre-treatment and precision spraying to environmentally friendly curing, we provide turnkey engineering solutions that deliver high yield and low energy consumption.

1. Challenges in the Industry (The Pain Points)

Standard spraying equipment often fails when dealing with narrow-neck containers. Our customers usually face:

- High production capacity: Customers have high production capacity requirements, which ordinary suppliers cannot meet

- Environmental pollution: Due to the harsh workshop environment, there will be dust in the air, which will cause defects on the sprayed products.

- High defect rate: Manual or inaccurate coating can result in inconsistent transparency and color, which is unacceptable for automotive parts brands

2. Our Specialized Solution (The Innovation)

We have engineered a specialized system to overcome the limits of micro-diameter coating:

- Exclusive fixtures: Based on the customer's production volume and product characteristics, design exclusive turntables and string fixtures to ensure production meets standards.

- Cleanroom: Design a cleanroom according to the customer's required cleanliness level to ensure compliance with acceptance standards

- Advanced Atomization Control: High-precision pressure regulation prevents "paint bounce-back," ensuring a smooth, mist-free application even in confined spaces.

3. Real Results for Your Business (The Value)

- Zero-Defect Production: Boost your yield rate from 60% to over 98%, meeting the highest quality standards for auto parts.

- 25% Paint Savings: Precision targeting reduces overspray and material waste compared to traditional "flood" coating methods.

- Mass Production Ready: Fully automated cycles allow for high-volume output (thousands of units per day), replacing 3-5 manual operators.

- Ready to Upgrade Your Production Line?

- Contact our engineering team today for a FREE technical consultation and a customized ROI analysis.

FAQ

Tell us about your project requirements and we will figure out a solution that will meet your budget and design expectations.